-

tel:

+86 151 5158 9048 -

email:

jay@alps-machine.com

36000BPH Full Automatic Pet Bottle Blowing Filling Capping Combiblock Water Machine

36000BPH Full Automatic Pet Bottle Blowing Filling Capping Combiblock Water Machine

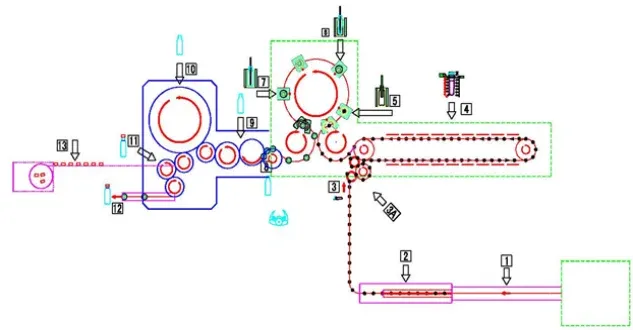

The combi block blowing, filling, and capping machine is based on the "blowing unit", "filling unit", and "capping unit". Through the comprehensive application of multiple disciplines such as light, machinery, electricity, and gas, the servo system is used for synchronous control to achieve integrated control and production of multiple unit equipment. This machine eliminates the equipment for empty bottle conveying and bottle washing on conventional beverage filling production lines, greatly saving the user's production line area, reducing the use of bottle flushing water and energy consumption of empty bottle conveying fans during operation, reducing a large number of intermediate transmission links, more reliably ensuring the cleanliness and hygiene of the entire equipment, and better helping users improve the production efficiency of the entire line, reduce investment costs, energy consumption, and equipment maintenance costs.

|

No. |

Belong To |

Name |

Brand |

Origin |

|

1 |

Main Electrical Components |

Touch Screen |

Siemens |

Germany |

|

2 |

PLC |

Siemens |

Germany |

|

|

3 |

Frequency Converter |

Danfoss |

USA |

|

|

4 |

Breaker |

Schneider |

France |

|

|

5 |

Reflective Plate |

Banner |

USA |

|

|

6 |

Photoelectric Switch |

Banner |

Germany |

|

|

7 |

Contactor |

Schneider |

France |

|

|

8 |

Proximity Switches |

SICK |

Germany |

|

|

9 |

Intermediate Relay |

Schneider |

France |

|

|

10 |

Main Motor |

Servo Gear Motor |

LUZE OR SEW |

Germany |

|

11 |

Filling Level Correct System |

Sanitary Centrifugal Pump |

Yuanan |

ABB Motor From China |

|

12 |

Exhaust Control Components |

U-Ring |

Rescort |

Taiwan |

|

13 |

Filling Valve |

Glyd Ring |

Trelleborg |

USA |

|

14 |

Filling Valve/Lifting Cylinder |

U-Ring |

Igus |

Germany |

|

15 |

|

Self-Lubrucating Bearings |

Rescort |

Taiwan |

|

16 |

Static And Dynamic Seal |

Solenoid Valve,Cylinder,Air Handing |

Igus |

Germany |

|

17 |

Pneumatic Components |

Solenoid Valve,Cylinder,Air Handing |

Trelleborg |

USA |

|

18 |

|

Solenoid Valve,Cylinder,Air Handing |

FESTO, SMC |

Germany |

|

19 |

|

Pipeline Valves |

Libaijia |

Made-in-China |

|

20 |

|

Rotary Support |

Fangyuan |

Made-IN-China |

|

21 |

Window |

Hinge |

|

|

|

22 |

Window |

Big Handle |

|

The PET preform is transported to the PET preform bucket through a tipping machine, and then lifted to the PET Preform sorting machine through a lifting machine. The PET preform is arranged in a scientific flipping and removing device, and the regularly arranged PET preform enters the Preform feeding device through the PET preform channel. After inserting the preform head into the PET preform. the flipping guide rail flips the PET preform to the state where the PET preform mouth is facing downwards, to ensure that the Preform body is in the predetermined heating area. While the PET preform rotates, the heating chain drives the PET preform to move in a straight line, After several stages such as penetration heating, balanced solidification, and distributed heating, the heating of the PET preform is completed. The PET preform is then flipped to the state where the PET preform mouth is facing upwards through the flipping guide rail, and enters the bottle blowing machine through the PET preform production mechanism. The flexible and precise PET preform picking mechanical pliers grasp the PET preform and place it in the blowing mold. The PET preform undergoes stretching, first blowing, second blowing, and so on in the blowing mold The cooling and other processes are finally formed and taken out of the mold by the bottle picking mechanical pliers into the bottle discharge mechanism. Finally, the bottle is moved to the downstream equipment by the bottle discharge wave wheel.

High automatic, famous brand components for stability and increasing production efficiency, ensure consistency in production quality.

.png?x-oss-process=image/resize)